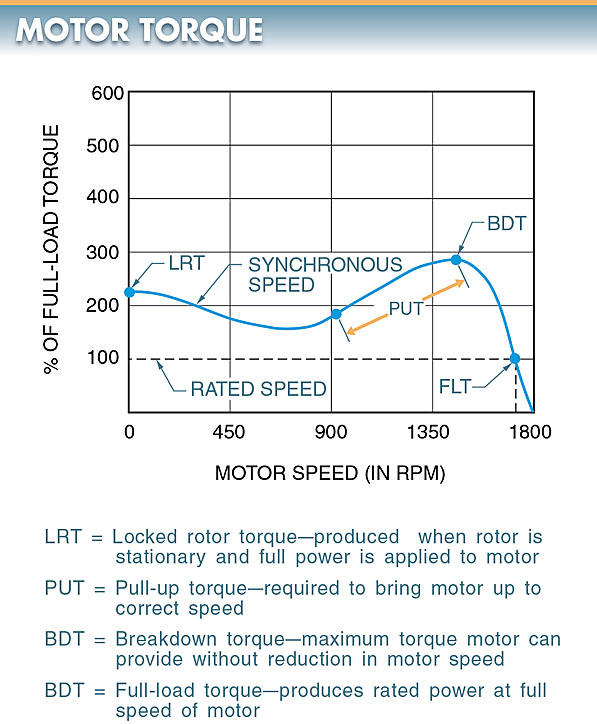

To turn over the load and keep it moving, an electric motor needs to generate a certain amount of torque. There are four distinct types of torque generated by a motor when it is coupled to a load.

Torque can be broken down into four categories: locked rotor torque (LRT), pull-up torque (PUT), breakdown torque (BDT), and full-load torque (FLT) (FLT). View Figure 1.

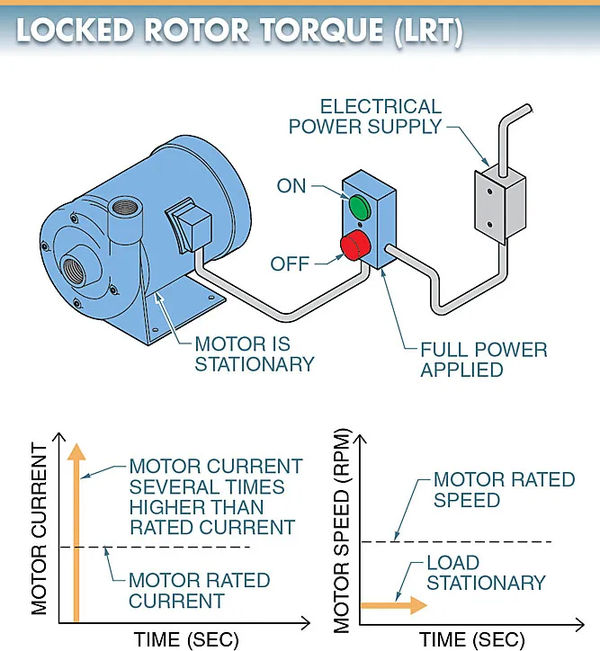

Locked Rotor Torque

Locked rotor torque (LRT) is the torque a motor produces when its rotor is stationary and full power is applied to the motor. See Figure 2.

The locked rotor torque may get the load spinning, but if the motor doesn’t have enough PUT, it won’t be able to reach its rated speed. When the motor reaches its rated speed, the full-load torque keeps the load spinning. The term “accelerating torque,” which is synonymous with “PUT,” is also used.

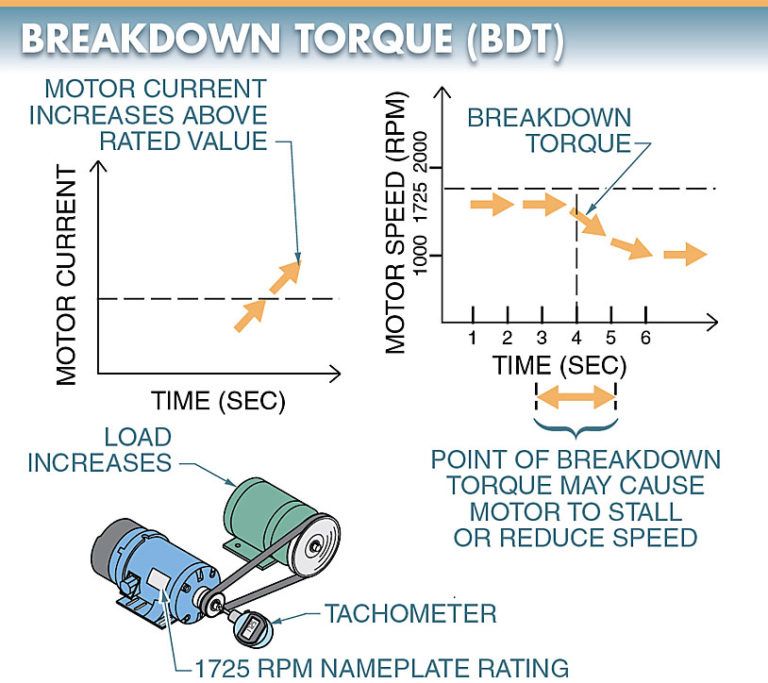

Breakdown Torque

Breakdown torque (BDT) is the maximum torque a motor can provide without an abrupt reduction in motor speed. See Figure 4.

Torque is increased by operating a motor under a greater load on its shaft. The motor stalls as the load increases beyond a certain point. The torque at which something breaks occurs here.

Figure 4. Breakdown torque (BDT) is the maximum torque a motor can provide without an abrupt reduction in motor speed.

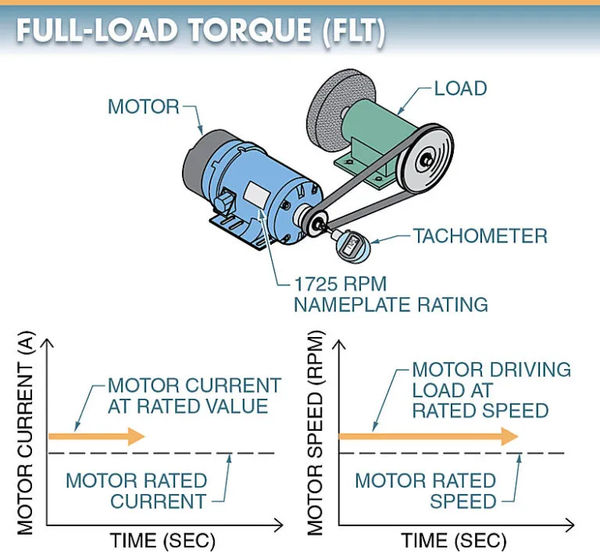

Full-Load Torque

Full-load torque (FLT) is the torque required to produce the rated power at the full speed of the motor. See Figure 5.

With the help of a horsepower-to-torque conversion chart, you can determine the amount of torque a motor generates at full power and speed (full-load torque).

Figure 5. Full-load torque (FLT) is the torque required to produce the rated power at full speed of the motor.

To calculate motor FLT, the following formula is applied:

Where

T = torque (in lb-ft)

HP = horsepower 5252 = constant

RPM = revolutions per minute

Example: Calculating Full-Load Torque

What is the FLT of a 30 HP motor operating at 1725 rpm?

Solution

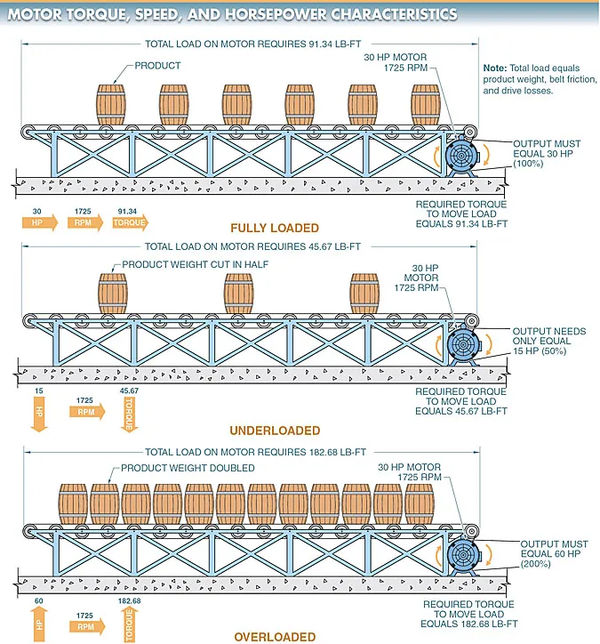

If a motor is fully loaded, it produces FLT. If a motor is underloaded, it produces less than FLT. If a motor is overloaded, it must produce more than FLT to keep the load operating at the motor’s rated speed. See Figure 6.

At maximum speed, the 91.34 lb-ft of torque produced by a 30 horsepower motor is an example. Assuming a rpm of 1725 and a torque of 91.34 lb-ft, a 30 HP motor will generate 30 HP.

The 30 HP motor only generates 15 HP at 1725 rpm if the load to which it is connected requires half as much torque (45.67 lb-ft). While producing only 15 horsepower, the 30 HP motor runs cooler and uses less power from the grid.

If the 30 HP motor is hooked up to a load that calls for twice as much torque (182.68 lb.-ft.) at 1725 rpm, the motor’s output must increase to 60 HP. The 30 HP motor generates more heat and uses more electricity from the grid. A properly sized overload protection device will cause the 30 HP motor to shut off from the power line before any damage can be done.