In this tutorial, we’ll go over the various AC Generator parts and provide visual representations of each.

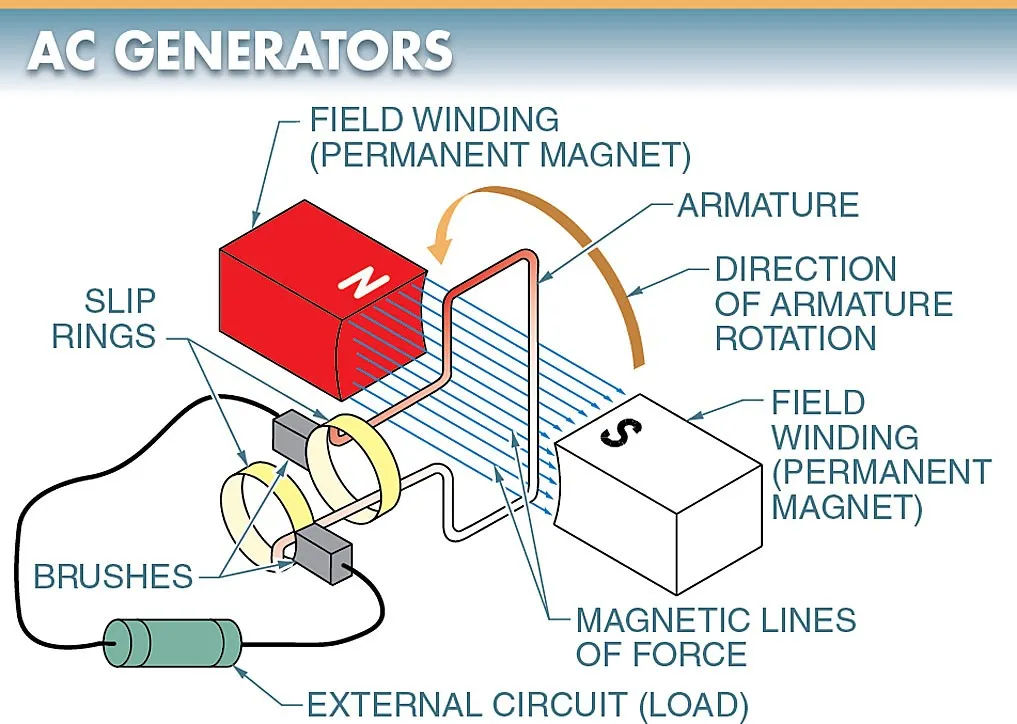

By means of electromagnetic induction, generators transform mechanical energy into electrical energy. Alternating current (AC) generators are devices that transform mechanical energy into AC voltage and current. Field windings or permanent magnets, a rotating armature, slip rings, and brushes make up an alternating current generator. To see this, please refer to Figure 1.

Field Windings

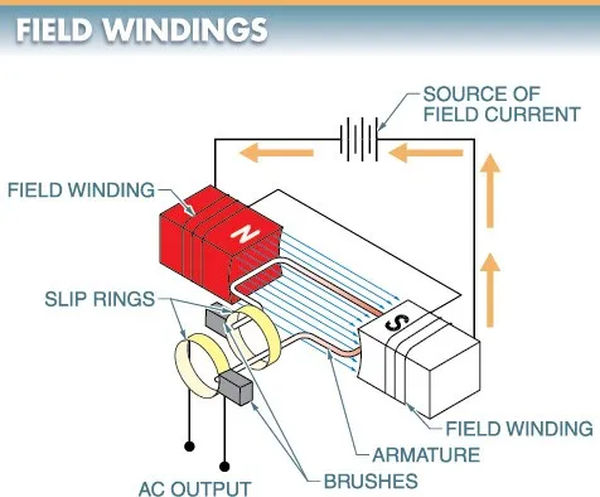

In a generator, the constant magnetic field is generated by a field winding, which is an electromagnet. In a generator, the magnetic field can be generated either by permanent magnets or by electromagnets. However, electromagnets are used in most generators, and current must be supplied to them. Refer to Figure 2.

Armature

In a generator, the armature is the coil of wire that rotates in response to the magnetic field. Many coils could be used to make up the armature. Coils have slip rings attached to their ends.

Slip Rings

In order to transmit the induced voltage to the brushes, it is typically routed through slip rings, which are metal rings attached to the armature’s ends. A voltage is produced in both halves of the armature coil as the armature rotates in the magnetic field.

Brushes

When connecting the armature to the external circuit, a brush slides against the commutator segments or slip rings.

It’s not too different to build and run an AC generator than a DC one. DC generators have a commutator that alternates the connections to the brushes every half cycle, which is the main difference between DC and AC generators. Because of this, the generator’s output voltage can be kept at a constant polarity. Slip rings are used in alternating current generators to connect the armature to the external circuit (load). The generator’s output voltage remains constant regardless of which way the slip rings are turned. The output is a sinusoidal waveform.

Armature Function

Each half of the armature travels at the same rate across the magnetic lines of force as the whole as it spins. Therefore, there is no difference between the voltage induced on either side of the armature.

The magnetic lines of force are slashed in opposite directions by each armature half. For instance, in a clockwise rotation of the armature, magnetic lines of force are severed from the bottom up and to the left by the lower half of the coil, and from the top down and to the right by the upper half of the coil. As a result, there is a polarity difference between the voltages induced on the two sides of the coil. Current flows in one direction when voltage is applied to the lower half of the coil, and flows in the opposite direction when voltage is applied to the upper half of the coil.

However, because the coil’s two ends form a closed circuit, the voltages add up. Because of this, the total voltage produced by a full armature rotation is twice that of each individual coil half. This combined voltage can be taken from the brushes that are connected to the slip rings and used in an external circuit.